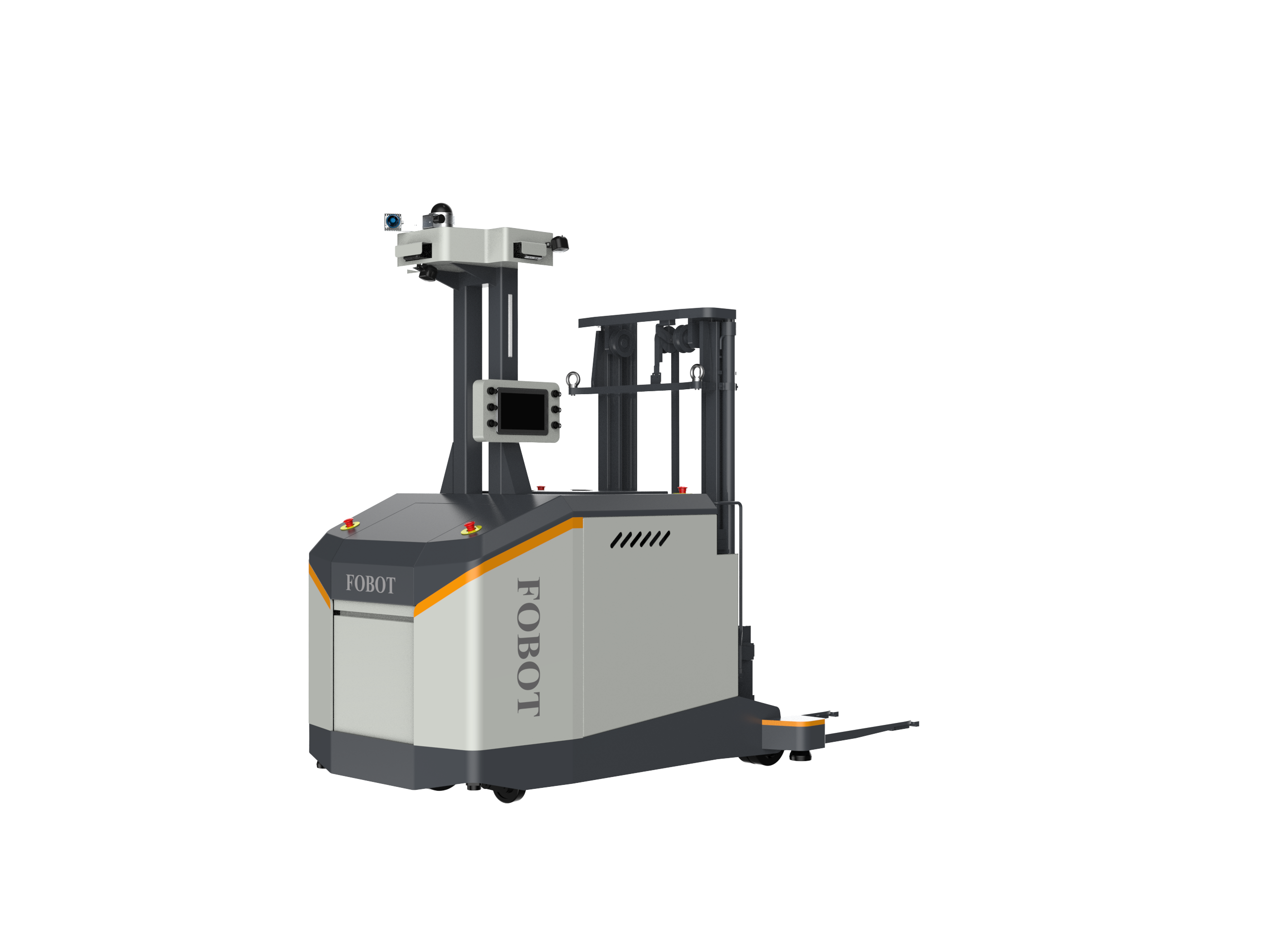

| Counterbalanced AMR | Stacker AMR | Pallet AMR |

|

|

|

In the dynamic landscape of modern industrial logistics, AMRs have emerged as transformative solutions for ground warehouse operations and lineside material handling. Specifically designed to address the challenges of high-bay warehouses with shelves exceeding 8 meters, the Counterbalanced AMR, Stacker AMR, and Pallet AMR models offer unparalleled efficiency, precision, and adaptability compared to traditional manual forklifts.

The Counterbalanced AMR operates on a sophisticated system that combines advanced sensor technology with intelligent navigation algorithms. Equipped with laser scanners, 3D vision systems, and LiDAR technology, it creates a real-time map of its environment, enabling precise movement and obstacle avoidance. Its counterbalanced design allows it to handle heavy loads without the need for additional stabilizing outriggers, making it ideal for both ground-level and elevated operations. The vehicle's lifting mechanism is engineered to reach heights of up to 8 meters or more, ensuring seamless access to high-bay storage locations.

The Stacker AMR is specifically tailored for vertical storage and retrieval tasks. It features a telescopic mast system that can extend to impressive heights while maintaining stability. This AMR utilizes a combination of magnetic tape, QR code navigation, and inertial measurement units (IMUs) to achieve sub-millimeter positioning accuracy. Its advanced control system ensures smooth and precise lifting and lowering operations, even when handling loads at maximum height. The Stacker AMR's ability to navigate narrow aisles—often as tight as 1.6 meters—optimizes warehouse space utilization.

The Pallet AMR excels in horizontal transportation and pallet handling. It employs a low-profile design with a built-in lifting mechanism that can effortlessly pick up and transport standard pallets. Using a combination of vision-based navigation and natural feature recognition, the Pallet AMR can operate in dynamic environments without the need for fixed infrastructure. This makes it particularly well-suited for lineside logistics, where it can deliver materials directly to production stations in a just-in-time manner.

Advantages Over Traditional Forklifts

1. Enhanced Safety

Traditional forklifts rely on human operators, whose judgment can be impaired by fatigue, distractions, or inexperience. In contrast, AMRs are equipped with multiple layers of safety features. For example, the Counterbalanced AMR's 360-degree obstacle detection system ensures that it automatically stops or reroutes when encountering obstacles, reducing the risk of collisions with personnel, equipment, or infrastructure. The Stacker AMR's precise height control eliminates the danger of overreaching, which is a common cause of accidents in high-bay warehouses. These safety features not only protect workers but also minimize damage to valuable inventory stored at height.

2. Operational Efficiency

AMRs operate 24/7 without breaks, shifts, or downtime for rest. The Pallet AMR, for instance, can execute continuous material flow between production lines and storage areas, maintaining a steady supply of components to meet production demands. This consistency reduces bottlenecks and ensures that production schedules are met reliably. Additionally, AMRs communicate with warehouse management systems (WMS) in real time, allowing for dynamic route optimization. This means they can avoid congested areas and adapt to changing operational needs, further enhancing throughput.

3. Space Optimization

In high-bay warehouses, space utilization is critical. Traditional forklifts require wide turning radii, necessitating broader aisles that reduce storage capacity. The Stacker AMR's ability to operate in narrow aisles, however, allows warehouses to increase storage density by up to 50%. Similarly, the Counterbalanced AMR's precise positioning capabilities enable it to work in confined spaces, maximizing the use of vertical storage. This verticalization of storage not only reduces the footprint of the warehouse but also minimizes the need for expensive real estate expansions.

4. Cost Savings

While the initial investment in AMRs may be higher than that of traditional forklifts, the long-term cost savings are significant. AMRs eliminate labor costs associated with human operators, including salaries, benefits, and training expenses. They also reduce operational costs by minimizing product damage, optimizing energy consumption, and extending the lifespan of warehouse infrastructure through careful handling. The Pallet AMR, for example, can reduce labor costs by up to 70% in lineside logistics applications while improving delivery accuracy.

5. Scalability and Flexibility

AMRs offer unparalleled scalability. As business needs grow or change, additional units can be easily integrated into the existing fleet without significant disruptions. The software-driven nature of AMRs also allows for quick reprogramming to adapt to new tasks or layouts. For instance, a warehouse transitioning from manual to automated operations can gradually introduce AMRs, ensuring a smooth transition. This flexibility is particularly valuable in industries with seasonal demand fluctuations or evolving production requirements.

6. Data-Driven Decision Making

AMRs generate a wealth of operational data, including travel times, load frequencies, and energy consumption. This data can be analyzed to identify inefficiencies, optimize workflows, and improve overall warehouse performance. For example, analyzing the routes taken by the Counterbalanced AMR can reveal opportunities to streamline material flow, reduce travel distances, and improve energy efficiency. This data-driven approach enables continuous improvement and strategic decision-making that is simply not possible with traditional forklifts.

Conclusion

In the demanding environment of high-bay warehouses and lineside logistics, the Counterbalanced AMR, Stacker AMR, and Pallet AMR AMRs offer a comprehensive solution that addresses the limitations of traditional forklifts. Their advanced working principles, combined with superior safety, efficiency, space utilization, cost savings, scalability, and data-driven capabilities, make them indispensable tools for modern logistics operations. By investing in these intelligent solutions, companies can achieve higher productivity, improved safety, and a competitive edge in the rapidly evolving industrial landscape.